PHONE

+989133114814

Esfahan - Iran

+989133114814

Esfahan - Iran

Utilizing a Skilled, Experienced, Creative, and Capable engineering team

Using precise and up-to-date CNC machines to produce the most advanced parts

Using the latest engineering softwares for design and construction

Manufacturing of precise and sensitive heavy parts and equipment with the highest quality

Heavy-Duty CNC Milling Services up to:

6000 x 3100 x 1450 mm

4000 x 1800 x 1500 mm

Reverse Engineering and Manufacturing of Special Industrial Parts & Equipment for Various Industries

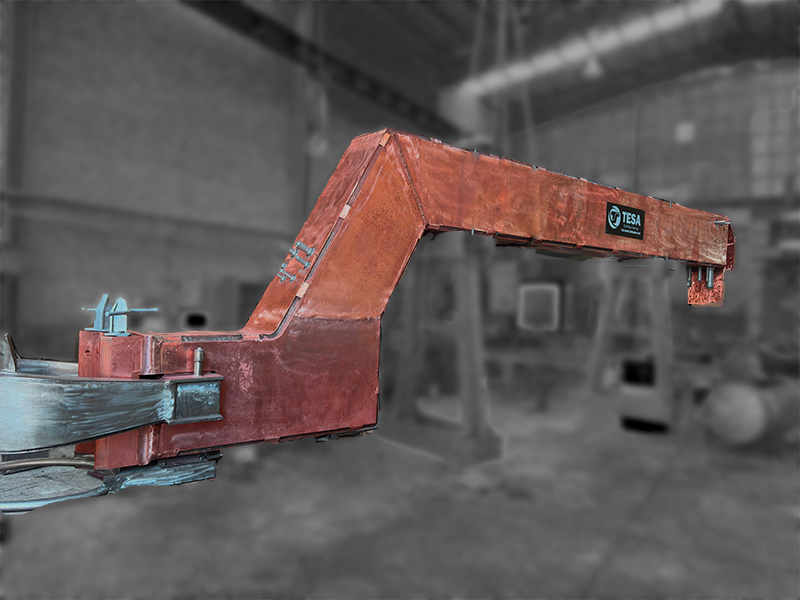

Design and Manufacturing of Electrode Arms for Electric Arc Furnaces (EAF) and Associated Components

Our company specializes in the complete design and manufacturing of these arms from the ground up. We also provide full refurbishment and overhaul services for existing electrode arms.

Equipped with 6-meter and 4-meter Gantry CNC Machines, TESA performs precision electrode arm machining.

Manufacturing of Premium Copper-Steel Bimetal Plates — engineered for exceptional mechanical strength and superior electrical conductivity — specifically for electrode arm body construction by TESA.

With hands-on experience refurbishing over 20 different arm models, we possess in-depth, practical knowledge of this product.

Utilizing cutting-edge engineering knowledge and actively developing our R&D unit focused on the design and manufacturing of Electric Arc Furnace (EAF) electrode holder arms

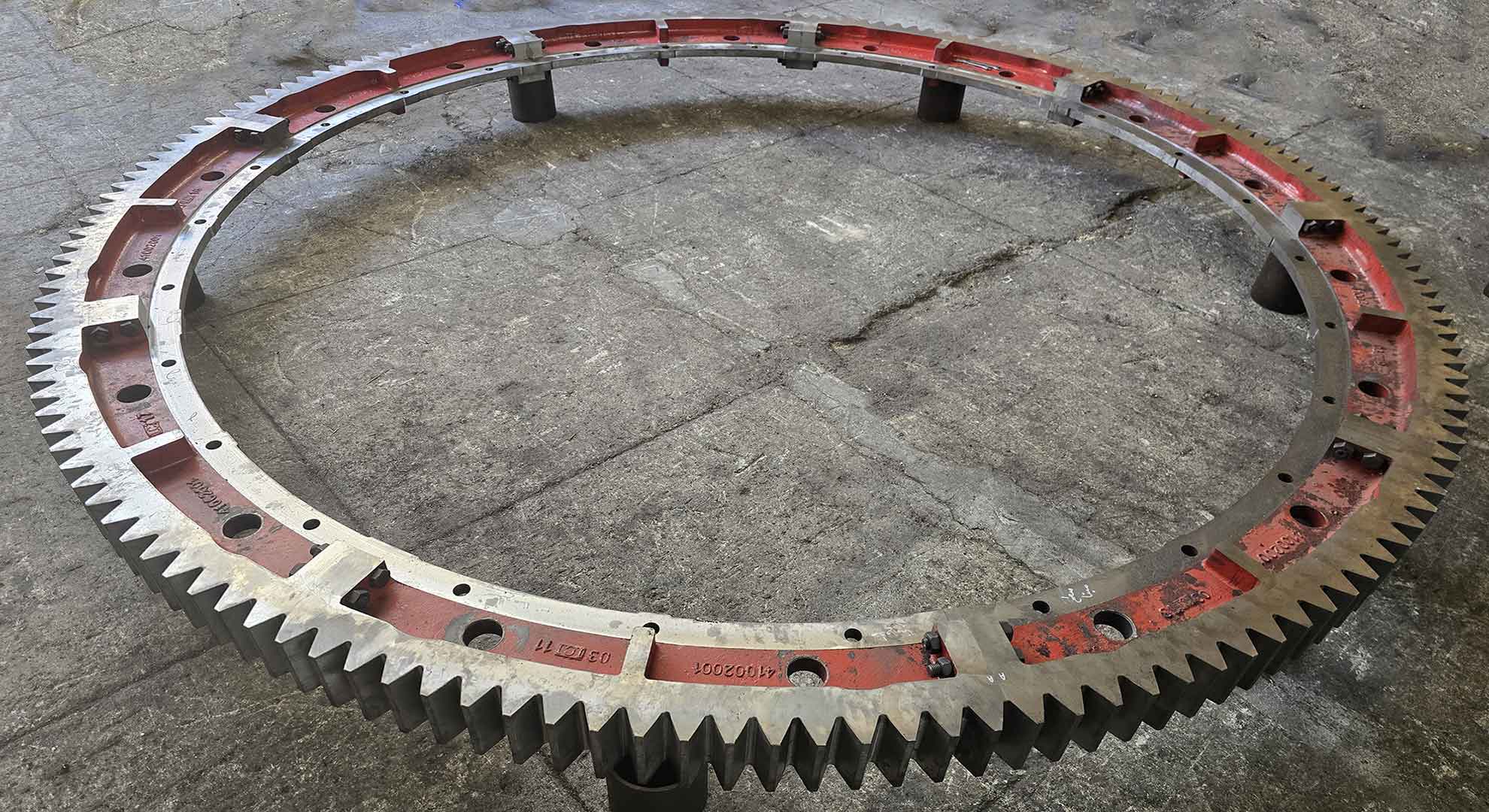

TESA Company, a leader in the precise, high-quality design and production of various ball mill gears, is ready to serve diverse industries. Our manufactured gears, known for their durability and exceptional performance, are the ideal choice for mining, cement, and other heavy industries.

These gears are typically machined in multiple segments and then assembled with utmost precision. The machining and gear cutting processes are carried out by TESA CO.

TESA Company has successfully manufactured steel and cast iron ball mills up to 10 meters in diameter for various industries.

Manufacturing of Copper Molds for Continuous Casting Lines for Various Steel Companies

Possessing 6-meter and 4-meter gantry CNC machines enables the integrated and precise machining of these molds.

Capability to machine and manufacture copper molds in various profiles according to customer specifications.

With over 40 years in the hydraulic industry, TESA specializes in heavy repair, design, and manufacturing of parts and equipment for these machines.

Capable of designing and manufacturing all mechanical components of these machines.

Specializing in the repair and manufacturing of all hydraulic and pneumatic system components.